Presents the integrity deterioration now and at any time in the future

Consulting services for equipment selection

Provides intelligent dashboards for improved decision making

Gives options for better optimization of rehabilitation, maintenance, and repairs

Wohner Power System has the knowledge and services to provide excellent solutions for the pipeline inspection industry. We have the technology, equipment and software to run with the best quality.

Providing pipeline inspection services by the priority of clients

All our analytical and inspection reports are prepared and provided by the latest analysis software.

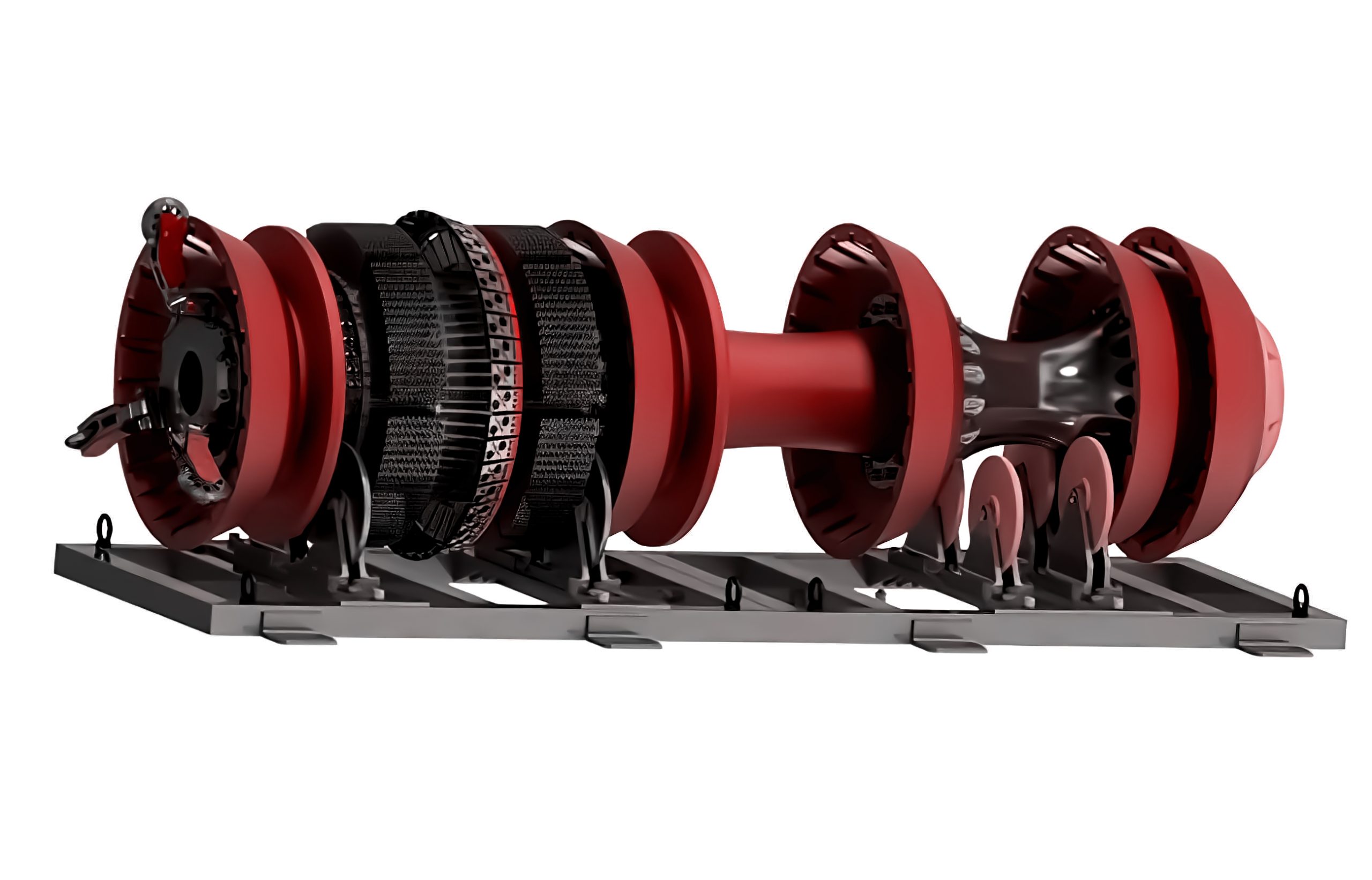

Provider of all Pigging services

Providing the best solutions and performing pipeline inspection operations in the most difficult conditions is one of the specialties of the Wohner Power System team.

Provide all executive services

We are ready to provide customer service with quality design, construction and execution.

Flexibility in any radius

Ability to cross the minimum bend

Crack detection with the latest technologies

Crack detection focusses on

liquid product pipelines

Information storage and transfer

Collect information in one round of inspection

Superb quality inspection

Accuracy in detecting pipeline defects

Please get in touch if you have a general Question about our services.

1549 ST. Georges Ave Unit 105 , North Vancouver BC Canada

Email: info@wohner.ca

Wohner is dedicated to ensuring optimal equipment availability, ultimately leading to the maximized return on investment for our customers. This commitment is upheld through the presence of localized service teams in every country of operation, along with strategically positioned stores stocked with genuine OEM-approved parts. Our extensively trained teams adhere to the highest standards, and we extend training programs to both our customers and staff to further enhance expertise and efficiency.