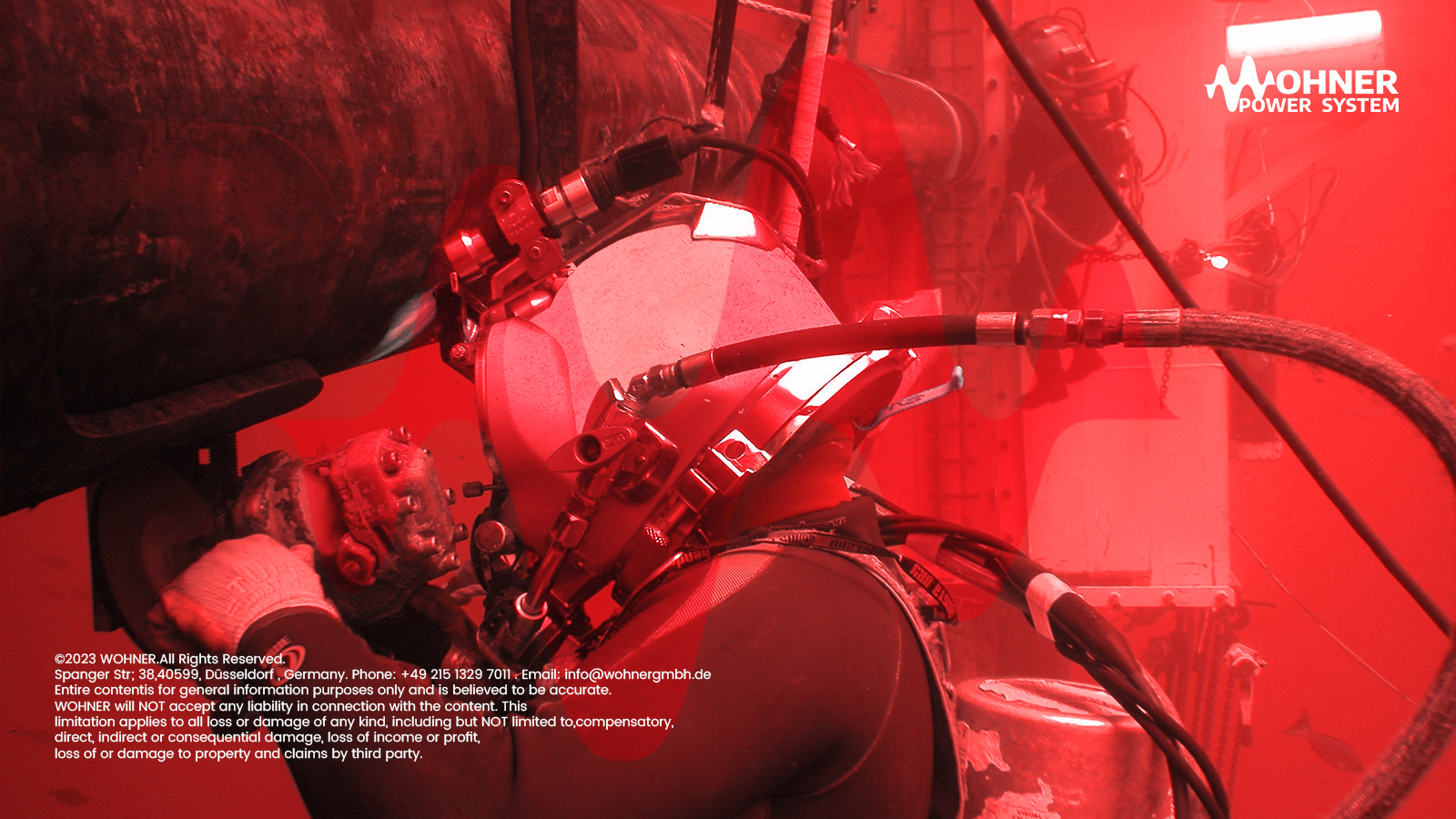

Wohner Power System Company is carrying out major repairs of your engine with the help of its specialists.

In order to ensure a generator has the highest levels of availability, scheduled maintenance should be completed at specific points in the operational life of the gas engine. The operational life is measured in number of actual operational hours (hours run). Each engine has a specific maintenance schedule that is be related to the quality of engine’s fuel gas. For example, natural gas is cleaner and less challenging than landfill or biogas. Attendance for replacement of consumables such as oil and filters typically occur every 1,000 – 2,000 operational hours. Scheduled intermediate services occur at 10,000-hour intervals.

Finally, the gas engine has a full overhaul at 60,000 hours of operation. At the 60,000-hour overhaul ideally the engine will be taken away from the site to be stripped down and fully serviced with specialised machinery. If we are provided enough notice, a reconditioned swing engine can be brought in at the corresponding time for the engine overhaul. This provides the lowest down-time for your generation plant. Alternatively, where it is not possible to remove the engine, it can be overhauled in situ. This is not an ideal situation and will take longer than using a swing-engine.

The gas engine product is renowned for its reliability, however from time to time there will be a need for unscheduled maintenance. This could be due to trips, problems with the fuel gas quality or problems with components. The best solution to counter any unscheduled maintenance is to ensure your gas meets the technical instruction for fuel gas quality and support this with a full maintenance agreement with Wohner Power System. It is also possible to set up remote monitoring of your gas generation facility. Remote monitoring enables you to monitor performance of your generator and to be notified via text message or e-mail about trips or unplanned shutdowns.

When your engine is overhauled, it may be possible to upgrade all components to the latest versions. This may provide additional benefits to the customer from increased generating efficiency.

• Service

• Commissioning

• Maintenance Agreements

• Technical Training

• Remote Monitoring and Diagnostics

• Field Service

• Spare Parts

• Overhauls and Repairs

• Conversions, Modifications and Upgrades

Wohner Power System helps Oil & Gas field services deliver fast and superior service for complex service-oriented jobs in rugged environments such as refineries or spill sites.

In Oil & Gas industry, the requirement for awareness and responsiveness of all things within the operation is essential. To streamline operations, reduce costs and improve profitability, organizations must be able to handle complex, diverse and changing mobile oil and gas field service management needs.

Facilities and services of operational

Wohner Power System provides operational readiness from the early stages of a project, accomplishing smooth transition from EPC to stable commercial operation through development of organizations, management systems and supply chains.

Through non-destructive inspections and other methods, Wohner Power System inspects and identifies available facilities and collects data for optimal maintenance programs with the customer. Based on the knowledge gathered in maintenance jobs, we develop the services provided to our customers by providing an advanced facility detection system with predictive maintenance functions.

Our experienced managers can increase the productivity and performance of your assets.

Wohner Power System provides manpower, experienced supervision and direct management to increase the performance of your assets, improve productivity and reduce your costs.

Our scalable maintenance method is designed to optimize maintenance operations and activities. We determine which of your people are equipped with the most efficient method to complete the work required and adjust their workload accordingly. Of course, we can provide training to fill any skills gaps in your workforce and ensure business competency.

We have the large inventory of gas engine spare parts. Spare parts availability is critical if engine downtime is to be kept to a minimum. Wohner Power System recognizes this fact and we hold the highest levels of stock of genuine spare parts. These spare parts can be dispatched at short notice where required.

Our spare parts team has a reputation for friendly and excellent service and is familiar with spare parts. This ensures that any problems with parts identification or supersessions are dealt with quickly and efficiently, thus ensuring that the correct item is supplied to the customer first time, every time. All spare parts are carefully stored on self-contained racking units in our quality controlled, purpose-built warehouse, operating to ISO9001 standards.

Our warehouse stocks are managed by the latest in computer software which replenishes parts when a minimum stock level is reached, ensuring a rapid turnaround on all purchase orders.

In addition to new genuine parts, Wohner Power System can also offer a wide range of re-conditioned and service exchange items. Our stocks include motors and alternators (swing-engines for major overhauls), all series cylinder heads, connecting rods, water pumps, turbochargers, intercoolers, starter motors and oil pumps.

In Wohner Power System also has a facility dedicated to the reconditioning of used cylinder heads. This facility reprocesses used cylinder heads, giving them a new lease of life and providing a quality control service to our customers.

We have long-term experience in engineering and project management. Wohner Power System has engineers and technicians who contribute in projects and in operating organizations in long or short-term assignments.

Wohner Power System is a specialist engineering company for the onshore and offshore industry. We have very high competence in advanced analysis, 3D modelling and production drawings and deliver projects from study stage to complete installation.

Our core services are within Installation, Rig Drill Support, IMR (Inspection Maintenance & Repair), Decommissioning, Utilities and Communication. We deliver engineering, project management & operational modifications.

As a leading and innovative provider of subsea engineering, Wohner Power System is proud to send senior pipeline engineers to the field to carry out important operations. Our expertise in the pipeline field includes advanced analysis and geotechnical support.

Wohner Power System provides a range of services including integrated maintenance and construction project delivery, commercial diving services, survey, geophysical and geotechnical services, and ROV services. Our extensive scope of services ranges from subsea stabilization, specialized subsea engineering solutions, and manufacturing to testing and assembly, and dry underwater welding.

Offshore projects such as the installation of platforms and offshore wind turbines would not be complete without transports that carry the necessary components and materials. But beyond that, the crews, staff and supplies for daily work life need to be carried to and from the shore.

WOHNER Company specialises in transport services for offshore projects. From crew transfers via ship or helicopter to supply runs for the provision of workers on offshore platforms. We specialise in shared cargo runs that combine shipments to different platforms to reduce costs and protect the environment. We also offer turnkey wind farm campaign solutions.

Crew changes occur whenever a current shift for staff working on an offshore platforms or wind farm ends and the next team arrives to relieve them. WOHNER offers complete concepts and takes care of the planning and realisation of the crew change. From the point of departure via the port or heliport to the platform or wind farm: We create a solution, individually tailored to your needs and with a single point of contact.

Whether the staff need to be transferred via helicopter or crew transfer vessel, we design an effective process for the crew change, arrange pre- and post-flight travel arrangements, check certificates of the crew, and conduct alcohol and drug checks to guarantee the safety of the people involved and make the crew transfer as easy as possible.

During the construction phase and even after a platform or wind farm has been installed, materials and supplies for the crew need to regularly reach the platforms. In return, waste disposal is needed. With our regular shared or single supply runs, WOHNER supplies your platform or jack-up barge offshore. Our platform supply vessels meet modern quality requirements and are all fitted with a DP2 (dynamic positioning) system.

Wohner Power System Group’s capability to deliver lump-sum turnkey EPC and its operating and maintenance expertise enhance our early engineering solutions, allowing us to recommend best-fit, constructible and operable solutions benchmarked against real-time procurement data and schedules. In addition, our extensive procurement benchmark database means that we can identify the most accurate prices currently available.

Our market offerings range from small reimbursable person-hour projects to major brownfield modification projects and call-off contracts, engineering services framework agreements and other performance-based strategies.

And depending on your objectives, we can fast-track our projects by seamlessly integrating early engineering and execution activities to improve schedule – in some cases by up to 12 months – and accelerate revenue recognition.

No matter the size of the project, we pride ourselves on challenging conventional thinking at the outset, bringing in our operations and construction expertise at the earliest stage to ensure our solutions are safe, technically sound, fit for purpose and cost-effective.

Project management services are one of our primary programs.

Large and complex projects require strong management and control to reach a successful conclusion.

Wohner Power System uses internationally recognized project management frameworks and processes as part of our quality management system to manage and control all our projects, whether these are engineering, procurement, construction or commissioning projects.

Our people have proven delivery capabilities, from the concept stage to execution, delivery and start-up.

Scale and complexity are never a problem for us. We have the workforce to cover projects of any size, and we tailor our teams based on the individual requirements of the client and project.

Solutions include operations readiness, maintenance, inspection, inventory optimization, and late-life asset management and decommissioning strategies.

Our fit-for-purpose business processes are designed to drive operational excellence that can integrate seamlessly with your existing systems.

Our technical management capabilities span:

Combining our operations capability with our wider life of asset services enables us to provide integrated solutions incorporating engineering, well engineering and training capabilities.

As a Service Operator, we provide competent people to staff your asset. Our Competent Person Profiles support these people to ensure the right people are in the right roles and have the necessary support for their personal development. In addition, a robust communications function ensures all personnel understands all core information and that campaigns around targets reach and are adopted by all employees.

We provide a range of comprehensive project management and engineering services across the entire asset life cycle.

We combine specialist pipeline engineering studies with subsea capabilities and the development of sizeable multi-discipline oil and gas development projects to develop specialist pipeline management solutions.

Wohner Power System combines creative thinking with practical experience and data from projects and operations to help unlock value from energy assets.

Our engineering and consultancy services span the energy asset life cycle, from concept design, screening and selection through engineering into project execution, pre-operations, and operations support through late life and decommissioning.

Our experienced, multi-disciplined teams have a rich skillset enabling us to solve the most complex project challenges. We support across the energy landscape, from oil and gas to services supporting broader decarburization objectives, offshore wind, and other clean energy sectors.

Focused on supporting at the earliest project stages, we provide services to support field development planning, concept design, screening, and selection to help smooth the patch to project sanction. We use our EPC experience and operations know-how to shape our solutions so that your project can progress with robust designs, costs, and schedule estimations that can be trusted.

Our project execution services span engineering execution, detailed design, procurement, commissioning, and site support. We can provide skilled, experienced project management teams to support your projects. Our engineering team is multi-disciplined and has experience delivering both early engineering and detailed design. This capability is complemented by a solid technical consultancy team, enabling us to advance even the most complex projects.

Wohner Power System asset management solutions team is uniquely placed to help improve the performance of assets

We are unique in that we use insights and standard data sets from operating assets and learnings from historical maintenance builds to deliver optimized maintenance and integrity regimes.

Our understanding of the issues that affect asset performance and access to actual operating data allows us to create solutions that improve safety and integrity, Increase reliability and availability, Reduce cost, Ensure compliance, and enhance risk management.

We not only identify opportunities for improvement but implement those measures, too, through our integrated services. Our services support the operational life cycle, from pre-operations to late life.

Please get in touch if you have a general Question about our services.

1549 ST. Georges Ave Unit 105 , North Vancouver BC Canada

Email: info@wohner.ca

Wohner is dedicated to ensuring optimal equipment availability, ultimately leading to the maximized return on investment for our customers. This commitment is upheld through the presence of localized service teams in every country of operation, along with strategically positioned stores stocked with genuine OEM-approved parts. Our extensively trained teams adhere to the highest standards, and we extend training programs to both our customers and staff to further enhance expertise and efficiency.